Pallet Racking Installation | London Case Study

CLIENT BACKGROUND

A client based in Park Royal, London, required an overhaul of their existing pallet racking system to accommodate a new product line.

LOCATION

Park Royal, London

OBJECTIVE

To modify and extend the existing pallet racking infrastructure to suit the requirements of the new product line. This included stripping down and rebuilding their existing racking and installing mesh enclosures, guide rails and end barriers.

CHALLENGES

The project faced the challenge of stripping and installing the new racking within a tight timeframe while ensuring minimal disruption to ongoing operations. To ensure the project was ready for the new product line, installation needed to be completed within 4 weeks.

SCOPE OF WORKS

Strip and Rebuild Pallet Racking:

BSE UK dismantled the existing pallet racking setup and rebuilt it to the new design specification. This involved configuring different bay types and levels to increase storage capacity. The specification included:

Bay Type 1

- 7000mm H x 2500mm D x 3000mm clear entry.

- 3 timber decked levels per bay.

- 6000Kgs SWL per bay.

Bay Type 2

- 6000mm H x 1000mm D x 3000mm clear entry.

- 14 timber decked levels per bay.

- 6300Kgs SWL per bay.

Layout Details

- 1 single entry run comprising of 9 type 1 bays.

- 1 single entry run comprising of 9 type 2 bays.

- 2 double entry runs comprising of 9 type 1 bays back to back.

- 1 double entry run comprising of 9 type 1 bays on one side and 7 type 1 bays on the other side.

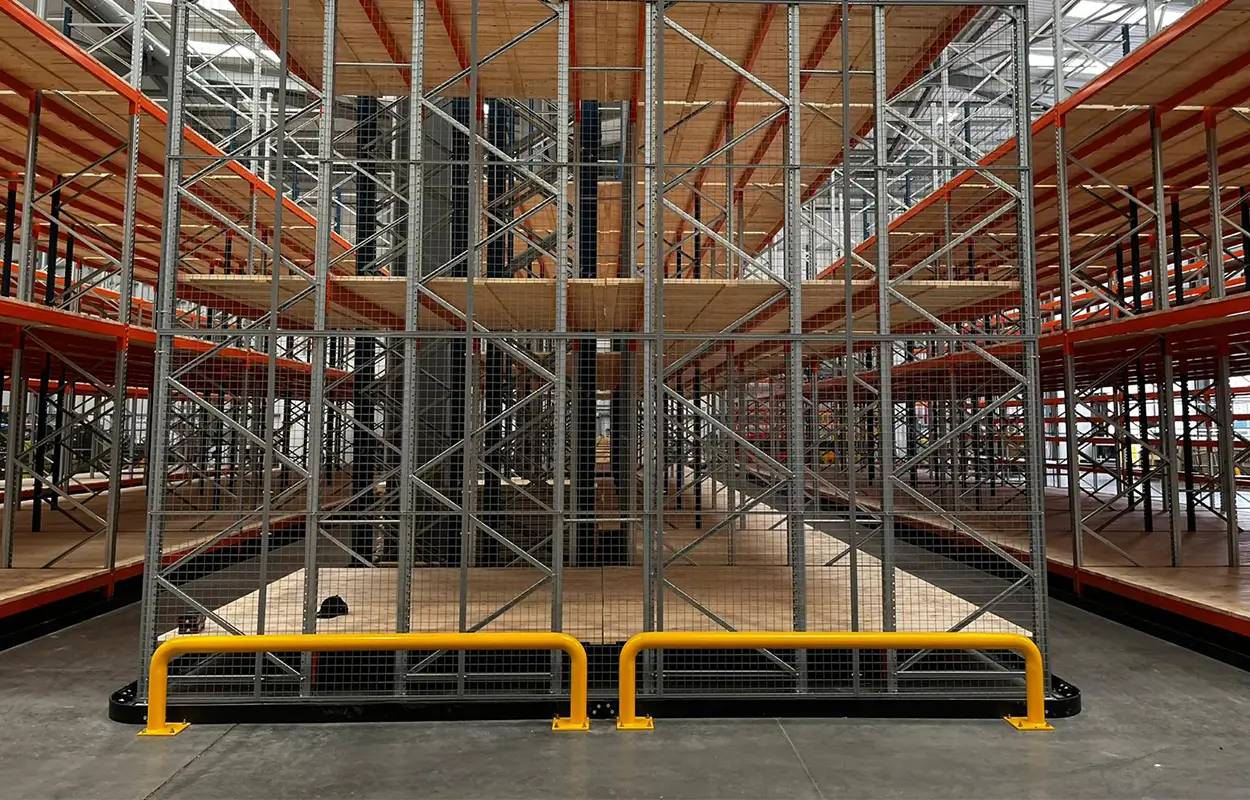

Mesh Cage Installation:

BSE UK installed 2 mesh enclosures to secure specific sections of the space, with a 4 sided enclosure and 3 sided enclosure at the end of the pallet racking. The specifications included angle frame steel partitioning, 2” x 2” x 10g mesh and a selection of finish options to meet the client's requirements. Enclosures were configured to accommodate single and sliding doors.

Guide Rails and End Barriers:

The project included the installation of racking protection including guide rails and end barriers to improve safety and reduce the risk of accidents. The specification included:

- 8 runs of 28m guide rail including 3 double lead ins and 2 single lead ins.

- 1 tubular end barrier 500mm high x 1000mm wide.

- 7 tubular end barriers 500mm high x 2500mm wide.

FINISH

To improve durability and deliver the project to the client’s specification, beams were painted orange and frames were painted blue.

ANTI-COLLAPSE MESH

Full-height anti-collapse mesh was installed across all designated runs as part of the project, with specified dimensions and finish to meet the client’s requirements.

RESULTS

The successful completion of the project resulted in significant improvements for the client including:

- Enhanced Storage Capacity

- Improved Safety

- Minimal Disruption

- Improved Accessibility

- Improved Efficiency for the New Product Line

Additionally, the project went ahead of schedule and was completed within 3 weeks, 1 week ahead of schedule.

Check Out the Project Gallery Below

If you’d like to find out more about this project or how we could support your business, give us a call today on 0117 955 5211 or book a site survey with our expert team.